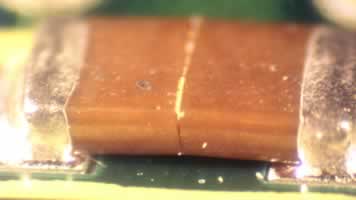

Cracked Ceramic Capacitor

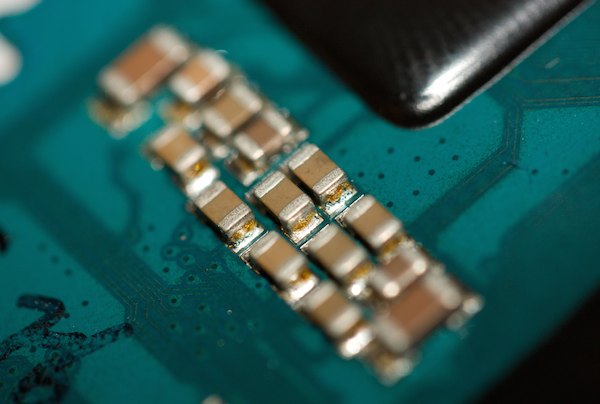

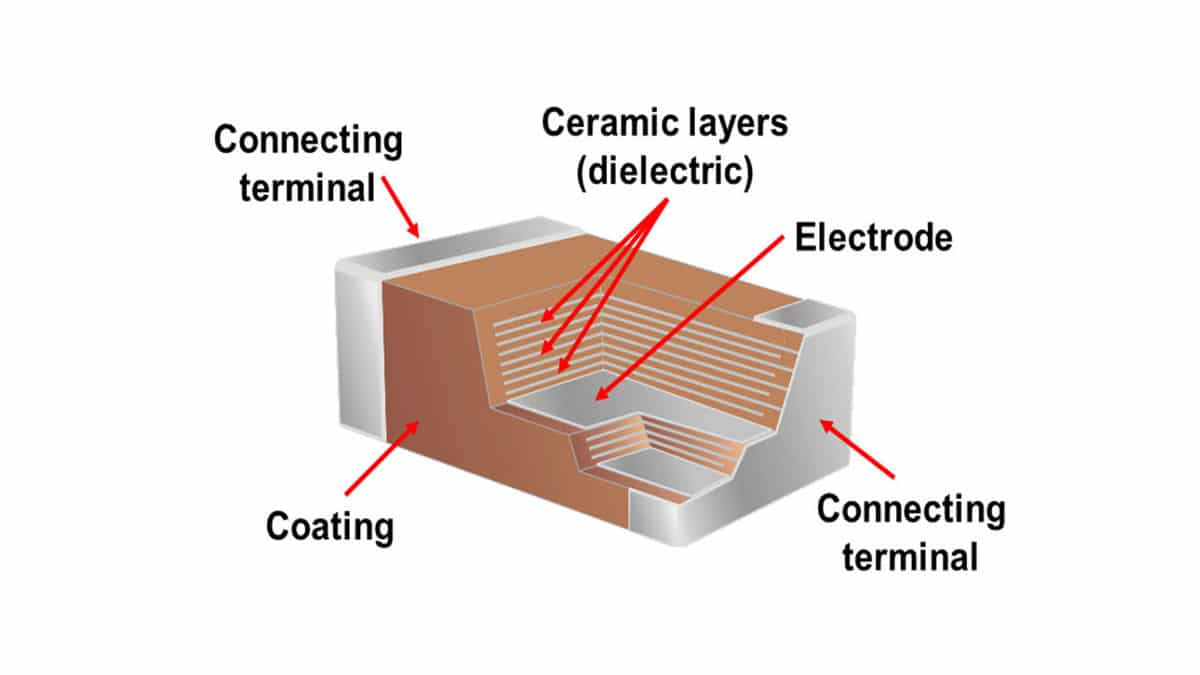

Multilayer ceramic capacitors mlcs have become one of the most widely used components in.

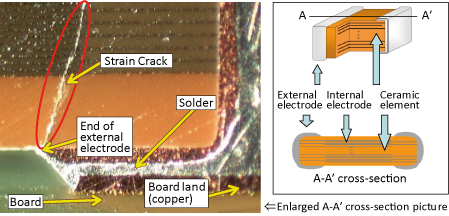

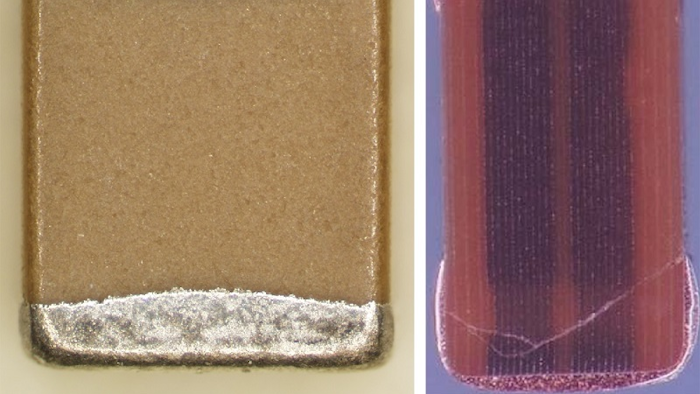

Cracked ceramic capacitor. As shown when the capacitor is cracked there is a dramatic drop in measured capacitance. Strain crack mechanism and preventive measures for multilayer ceramic capacitors. When a crack occurs on the element of an mlcc multilayer ceramic chip capacitor due to depaneling of the print circuit board screw fastening or shock from a vibration or a drop it may lead to a short circuit failure. When cracks occur in a chip multilayer ceramic capacitor due to mechanical or thermal stress being applied and cracks reach the active area of the internal electrodes figure 1 leakage may occur between the internal electrodes of that portion causing a deterioration short of the insulation resistance.

Major causes of solder cracks solder cracks on mlccs developed from severe usage conditions after going on the market and during manufacturing processes such as soldering. This page introduces major causes and countermeasures of solder crack in mlccs multilayer ceramic chip capacitors. Among failure modes there are open circuit failures and short circuit failures. As the ceramic capacitor is inherently rigid non elastic any.

Thermal shock has become a pat answer for all of these cracks but about 75 to 80 originate from other sources. My murata capacitor site application manual board bending stress you need to create an account with your company email address log in request access to each site and get a membership the article about clack of mlcc is here. If no crack appears the capacitors are able to withstand the wanted requirements. This condition will lead to a catastrophic failure of the.

A ceramic capacitor is a fixed value capacitor where the ceramic material acts as the dielectric. Small ceramic capacitor failures 3ddr is an instrumentation data recorder seven units were tested to failure in order to understand dominant failure modes root cause of failure was determined for all the failure mode for 4 out of the 7 was a small ceramic capacitor failure unit cause of failure f1540 capacitors c84 c85 open. Cracks in ceramic chip capacitors can be introduced at any process step during surface mount assembly. Cracked capacitor stress is a force which produces or tends to produce deformation and is measured as the force applied per unit of area.

These sources include pick and place. Applications and boards that specially require solder. The spreading of the cracks in the ceramic of the affected capacitors the fracture pattern includes the information about the nature and direction of the implied forces. Flex cracks provide an ingress for both moisture and contaminants promoting a short circuit within the capacitor.