Creating Your Own Basement Sub Floor

Yes you can build a 12 inch high basement subfloor and stay dry above everything but basement ceilings tend to be low.

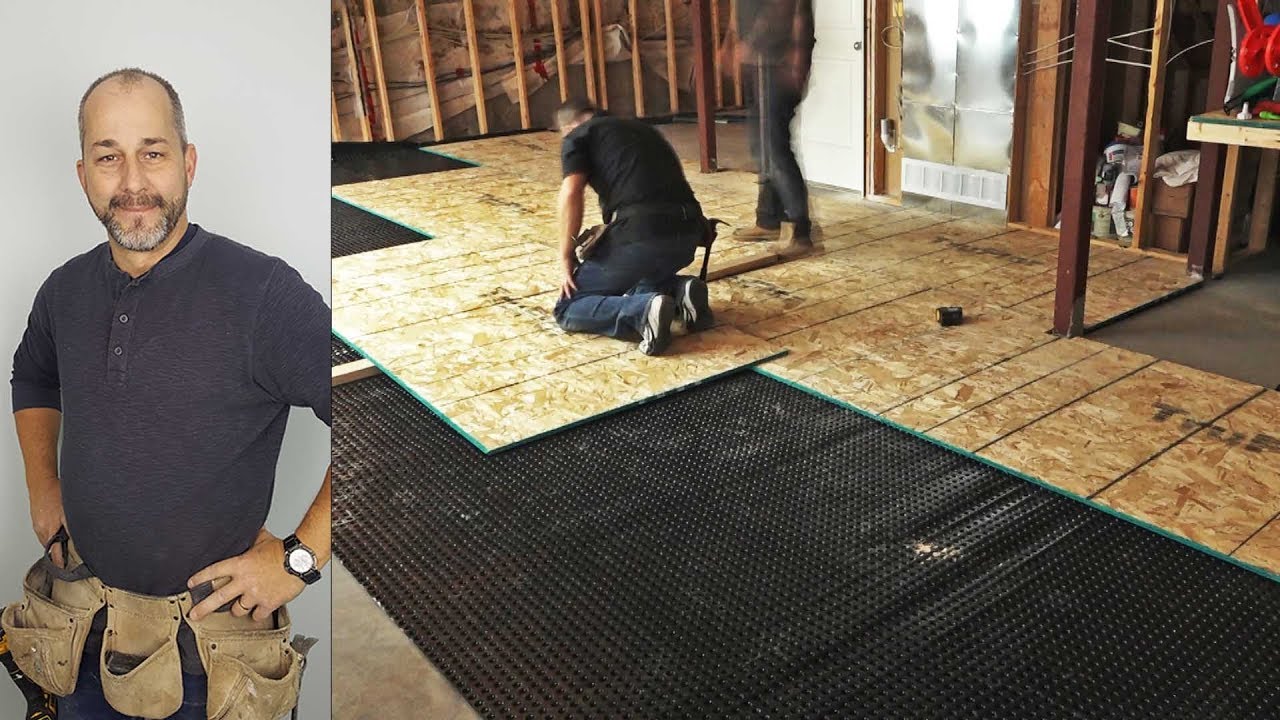

Creating your own basement sub floor. The subfloor definition is professionally listed as the foundation for a floor in a building. The panels must be installed on a level surface so the basement floor must be leveled beforehand. A self built basement subfloor will always be cheaper than a subfloor system. Carpet can be especially susceptible to moisture.

This will reduce the subfloor. Even an inch or two in elevation for your subfloor will make a noticeable difference. Think of it as an impenetrable barrier that keeps your basement floor dry. Full 8 foot tall basement ceilings in older homes are rare with 7 footers more the norm.

Check the flooring manufacturer s installation instructions before you make your choice. Make your curb out of 2x4 s. Keep your subfloor material and basement flooring off of the concrete. In this example building your own subfloor will cost from 750 to 1 000.

Is a subfloor necessary in the basement it will help you choose the correct subfloor for your needs. Wood panels such as plywood or oriented strand board are common subfloor choices. By successfully installing a basement subfloor you will keep your basement bone dry. This price is malleable and can be raised or lowered by purchasing different materials.

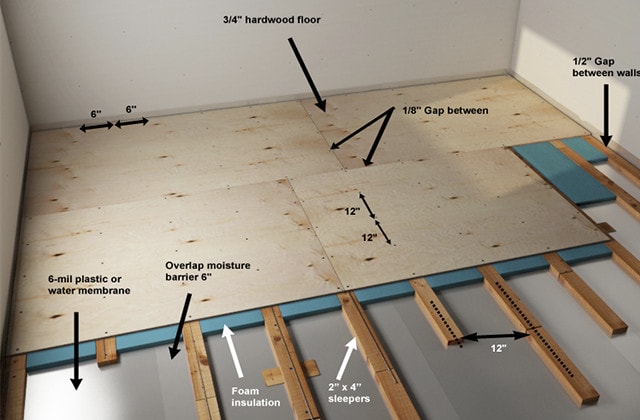

The plywood subfloor layer. Leaving out the rigid foam insulation will considerably cut down on costs. Basement subfloors can have different layers of protection. Also ensure that the nails in the boards are flush.

Try unique flooring ideas in your basement. Follow our helpful tips below before installing engineered floor panels in your basement. Go to the article. Before you start installing this final subfloor layer make sure your lattice is completely level.

Create a finished basement look with a subfloor. After creating your elevation your next layer of subfloor is the plywood or osb layer. Build your curb at the entry of the shower stall. However the first piece which is anchored into the concrete with 2 1 2 inch masonry screws must be pressure treated wood as it is resting directly against the concrete slab.

You may need to add to or shave the 2 4 boards to get a level surface. There are many different materials you can use for your floor. This is the best and most effective way to keep your floors dry. You can stack regular douglas fir 2x4 s on top of the pressure treated piece and nail.