Density Of Ceramic Composite Armour

To help you come up with a wise and informed decision here is a quick.

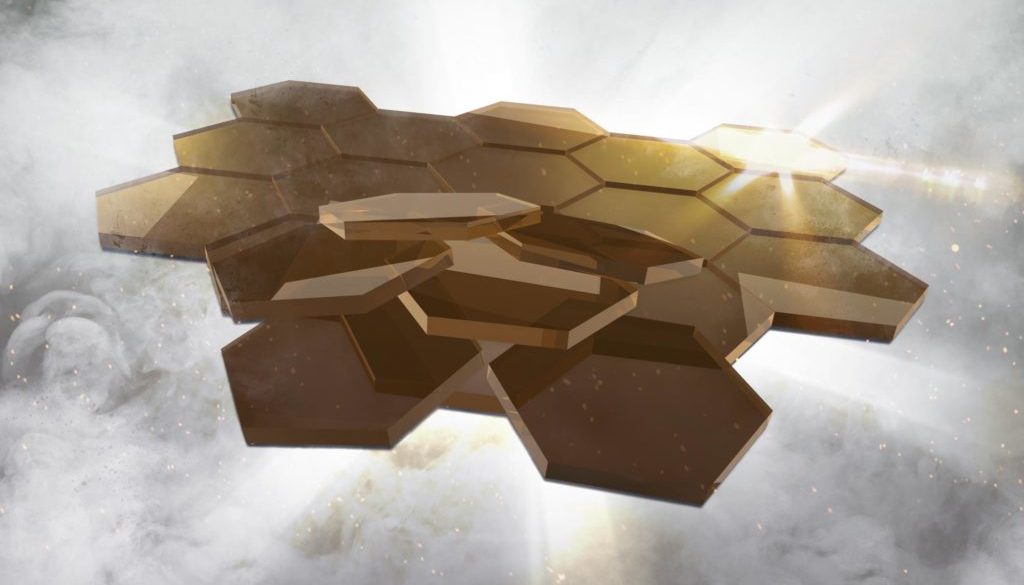

Density of ceramic composite armour. The natick ceramic composite body armor t65 2 chicken plate panel reflecting as it did the cook patent 493 went on to become the standard for all ceramic body armor since then. Chobham armour is the informal name of a composite armour developed in the 1960s at the british tank research centre on chobham common surrey the name has since become the common generic term for composite ceramic vehicle armour other names informally given to chobham armour include burlington and dorchester. We have collected a number of charts detailing applications and properties for some of the most commonly used ceramic materials. While the data in these charts is in most cases typical of what you will find from ceramic component suppliers it is only intended to be a general point of reference and should not be used for material selection or specification.

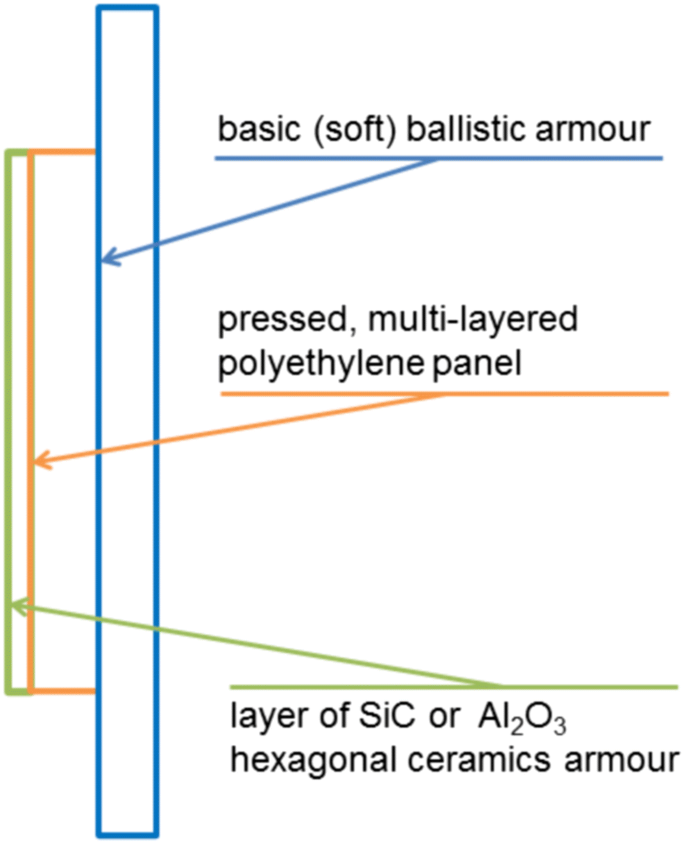

High cost processing hindrances and restrictions to predict ballistic performance from the properties of the material are some drawbacks of ceramic armors 3. The stiffen ing and structural enhancement of the individual. If you have ever purchased body armor before you probably know that you have the option of choosing between hard and soft armor plates. For example hexoloy silicon carbide sic specifically provides ballistic armor protection and bullet resistant composite armor for military personal vehicles aircraft and police.

The basic ceramic body armor breastplate insert plate concept since 1965 has comprised a contoured ceramic breastplate around 6 9 mm thick with thin frp. For example the t 64 turret front and cheek was originally filled with aluminum and then ceramic balls and aluminum whilst some models of the t. Protection for vip vehicles. The key benefits of a ceramic armor are.

Marine grade ceramic armor for use in medium and small size boats. Quantifying and optimizing ceramic armor systems require attention to the following factors where rha armor steel is the reference material in all cases. Projectile velocity for a given projectile type armor system and ad value at which 50 of impact events correspond to penetration and. Benefits of ceramic armor.

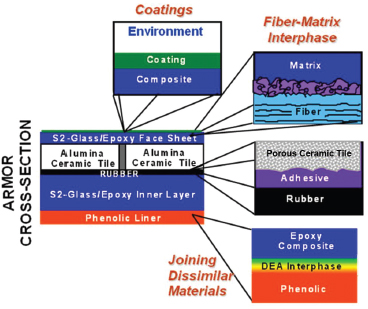

Areal density measured in kg m 2 the lower this is the more weight efficient the armor. Ceramic composite substrate adhesive in a composite armor system the ceramic is nor mally placed on the strike face preferably per pendicular to the expected threat. You need to decide whether you will go for hard steel ceramic or polyethylene plates. Polymer fibres composed of polyaramide polyethylene or poly propylene form the composite backing.

However besides those that primary decision there are still a few choices you have to make. Soviet main battle tanks from the t 64 onward utilised composite armor which often consisted of some low density filler between relatively thick steel plates or castings for example combination k.