Diamond Floor Polishing Process

The tomcat diamond polishing system will work with any of our disk floor scrubbers.

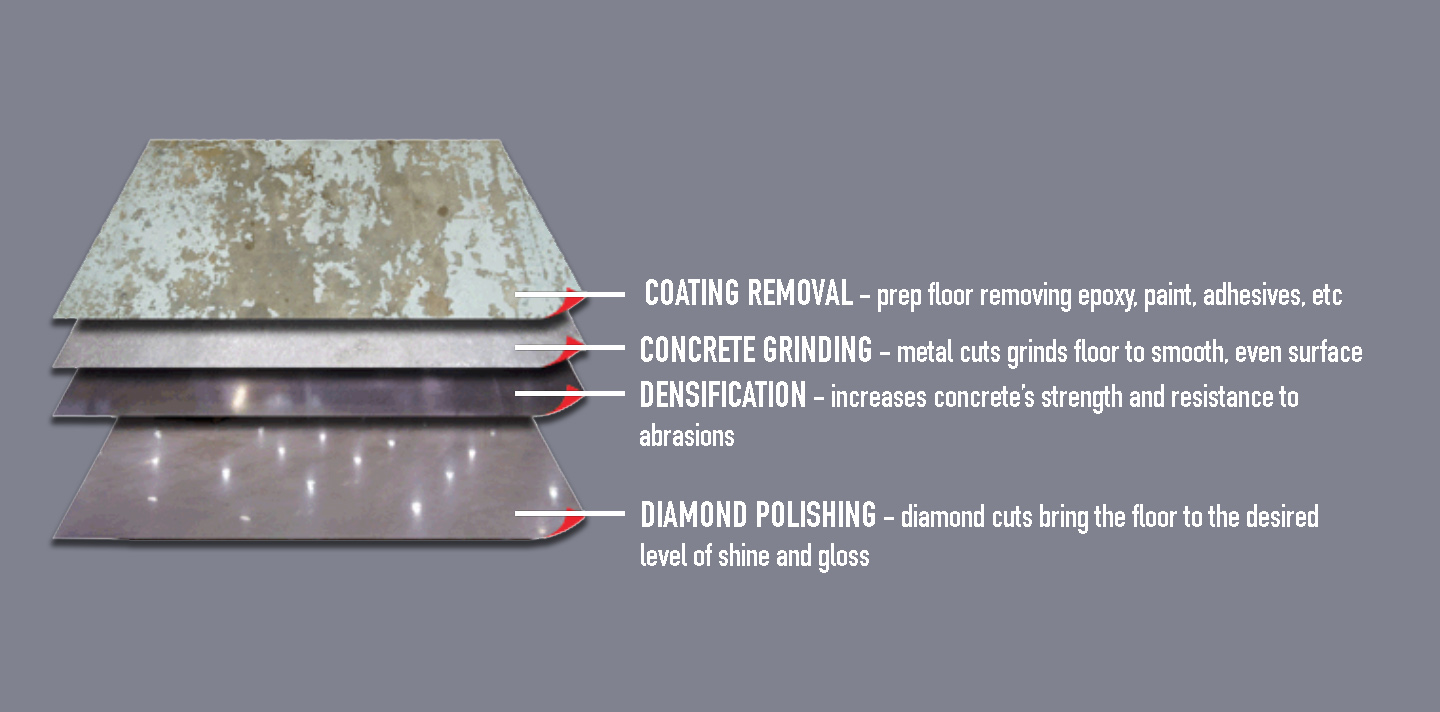

Diamond floor polishing process. Diamond floor solutions specializes in decorative concrete floor finishes concrete staining polished concrete floors terrazzo floors concrete floor coatings. Polishing is then performed by a 400 grit resin bonded diamond disc and then an 800 grit disc. Polishing is a unique multi step process of progressively finer grinding concrete or terrazzo floor surfaces through the use of diamonds and high technology equipment. The polishing process turns an ordinary floor surface into an impressive beautiful floor with a quality sheen color and the ability to prevent water and other contaminants.

Make an inspection after the 2 nd cut regarding. Apon completion of this cut it is often best practice to run over the floor with a finer diamond such as a 100 120 grit diamond disc which will remove any score marks. Crews use ever finger grits of polishing disks a process called lapping until the floor has the desired sheen. It is an eco friendly low maintenance flooring method that is the most durable and budget friendly alternative to marble tile or other surfaces.

Polished diamond grist may go as high as 3000. 3 the next steps involve fine grinding of the concrete surface using diamond abrasives embedded in a plastic or resin matrix. Costs for the diamond grinding floor polishing process would be worth it in the long run. Not only do you densify during the early stages but once it is brought up to 800 the stain has already been applied to the concrete floor prior to the actual shine.

These segments are coarse enough to remove minor pits blemishes stains or light coatings from the floor in preparation for final smoothing. Concrete polishing is an exceptionally beautiful option for your home or business. Once the multi step process of floor polishing is finish the system will actually continually improve the look of your floor every time you clean and polish it. Polishing process the process begins with the use of coarse diamond segments bonded in a metallic matrix.

Depending on the condition of the concrete this initial rough grinding is generally a three to four step process. Diamond floor solutions formerly know as diamond cleaning systems has been in the business of concrete floors for more than 10 years. A coat of stain guard used over the newly polished concrete surface is recommended. The final polishing stage.

Get a detailed summary of the floor polishing process including information on using planetary grinders chemical densifiers diamond tooling and more. A resin bond diamond cannot remove score marks and wears too fast on a coarse surface. Remove existing coatings for thick coatings use a 16 or 20 grit diamond abrasive or more aggressive tool specifically for coating removal such as a t rex tm.