Direct Metal Printing Ceramic Cores Aerospace Ohio

The designs of ceramic cores have grown increasingly complex in many aerospace and commercial casting applications.

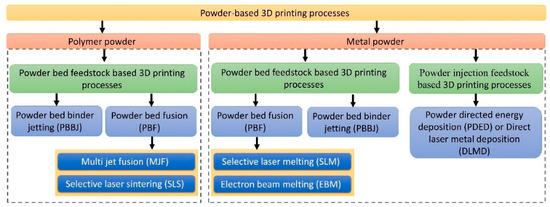

Direct metal printing ceramic cores aerospace ohio. With 3d printing a ceramic shell with integral cores may be fabricated directly from a computer model. For assistance contact acers customer service at 866 721 3322 or 614 890 4700. The large build volume fast build rate and use of standard foundry materials compatible with aluminum and magnesium casting material combine to make 3d printing an efficient replacement for traditional pattern production of metal based prototype castings in the aerospace industry. Ceramic shells for direct casting of metal parts three dimensional printing is the only process that fabricates ceramic molds directly from a computer model with no intervening steps.

Ranging from cores used to make complex cooling passages in airfoils to cores used to make oil flow channels in large housings. Fabrisonic an ohio based company specializing in metal 3d printing will debut its latest system using ultrasonic additive manufacturing uam technology the soniclayer 1200 machine at rapid. Is at the cutting edge of ceramic core technology. Exone sand 3d printers are capable of handling build sizes as large as 1800 x 1000 x 700 mm 70 x 39 x 29 in.

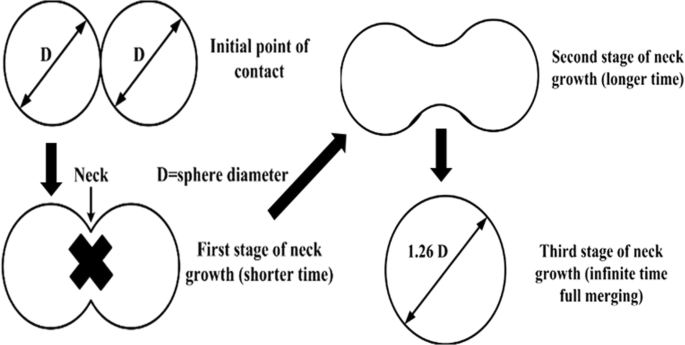

These cores are predominantly found in aerospace and industrial markets but there is a growing demand in the healthcare sports and automotive markets. A complete 3d printing offer dedicated to aerospace industry tooling and embedded parts manufacturing with over 30 years experience and a label en9100 iso9001 eca group plastic and metal finished parts manufacturing through our fleet of thirty industrial 3d printers with iso9001 certified technologies and materials and en9100 in progress. Ceramic cores are sacrificial ceramic structures primarily used for forming cavities that are too small or complex to be machined within investing casting procedures. In the machine a high precision laser is directed to metal powder particles to selectively build up thin horizontal metal layers one after the other.

Perfect 3d has the ability to rapidly produce some very challenging ceramic cores for use during the casting process. The american ceramic society 550 polaris pkwy ste 510 westerville oh 43082. Our direct metal printing service is the best option for stainless steel and bronze alloy manufacturing in quantities ranging from about 100 to 1000 parts. Our company is dedicated to providing quality products on time delivery and fair prices.