Dispatching Rules In Shop Floor Control

However the mbs rule may lose a chance to improve system performance by utilizing real time shop floor information that.

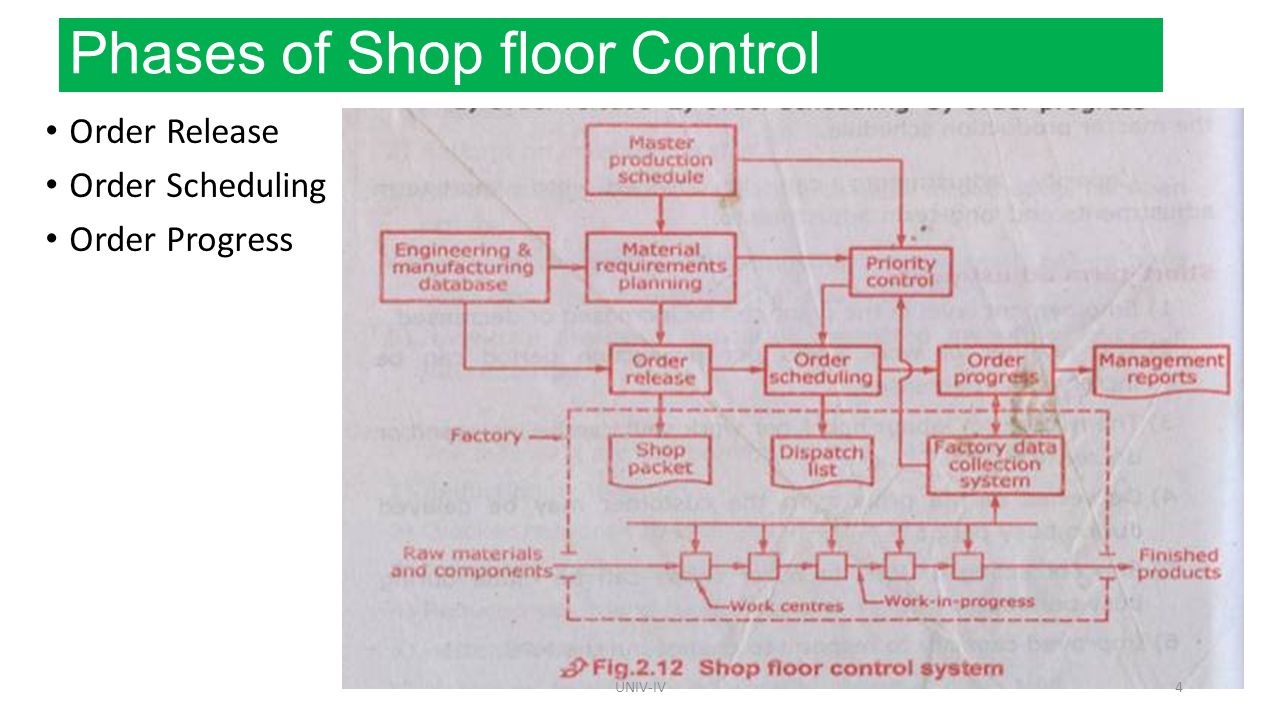

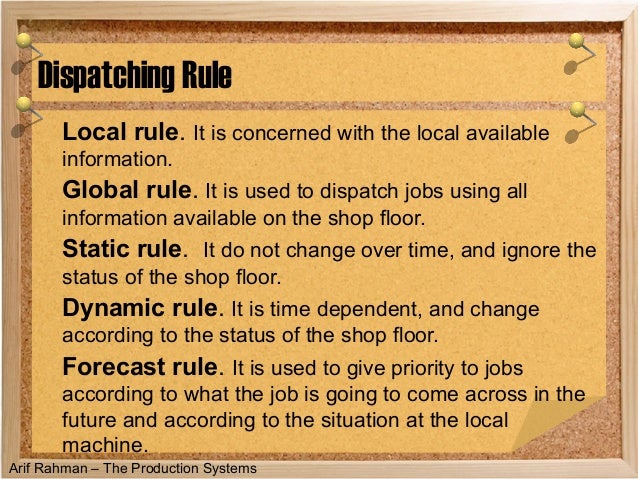

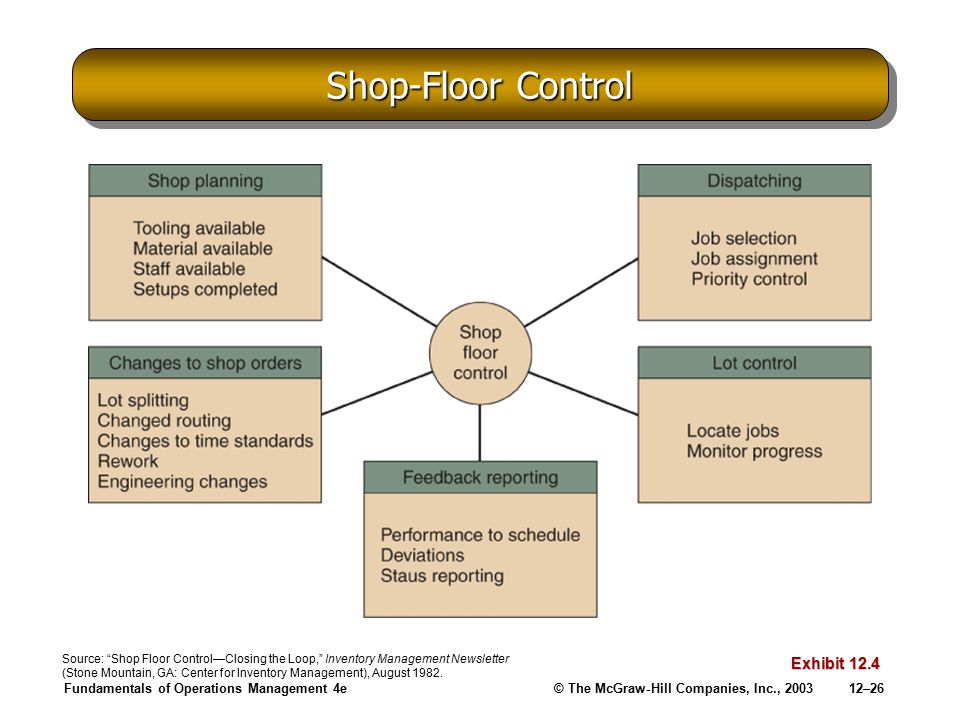

Dispatching rules in shop floor control. The mbs control policies are easy to implement on the shop floor dispatching for because it requires minimal computation with only local information such as current wafer lots waiting in queue. Meet due date so it is used as tool for shop floor control because of the ease of implementation quick in reacting to the changes encountered on the shop floor low computation requirement and flexibility to incorporate domain knowledge and expertise. The apics body of knowledge defines five different commonly used dispatching rules. First come first served jobs are worked on in the order they are received at the work center.

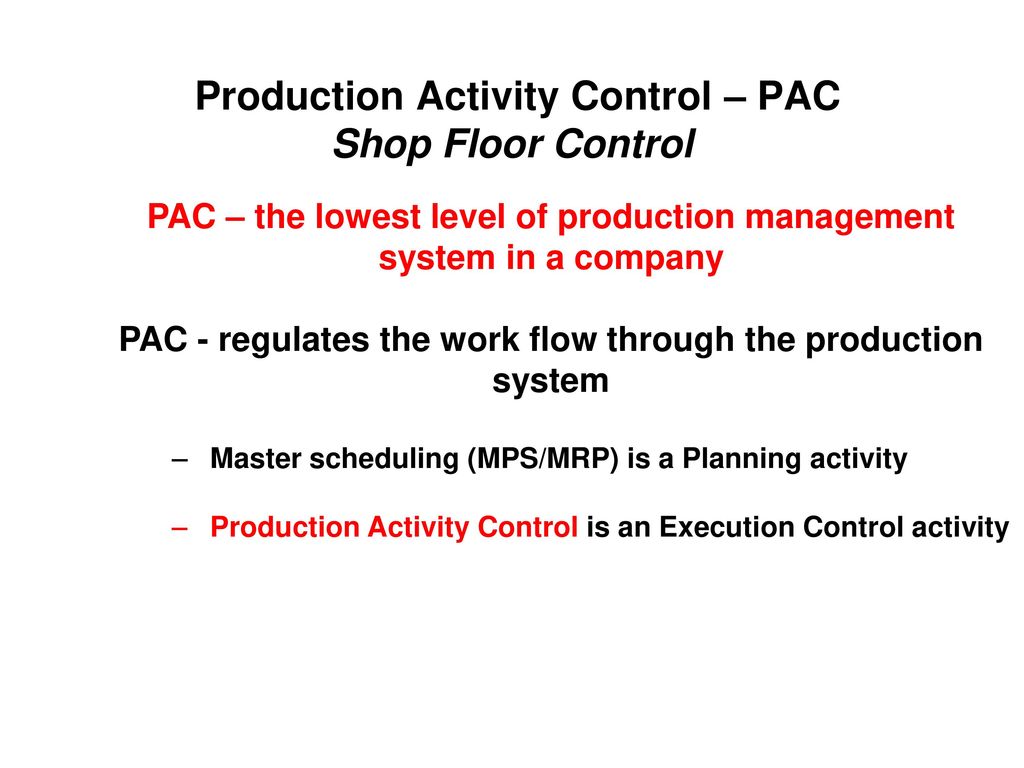

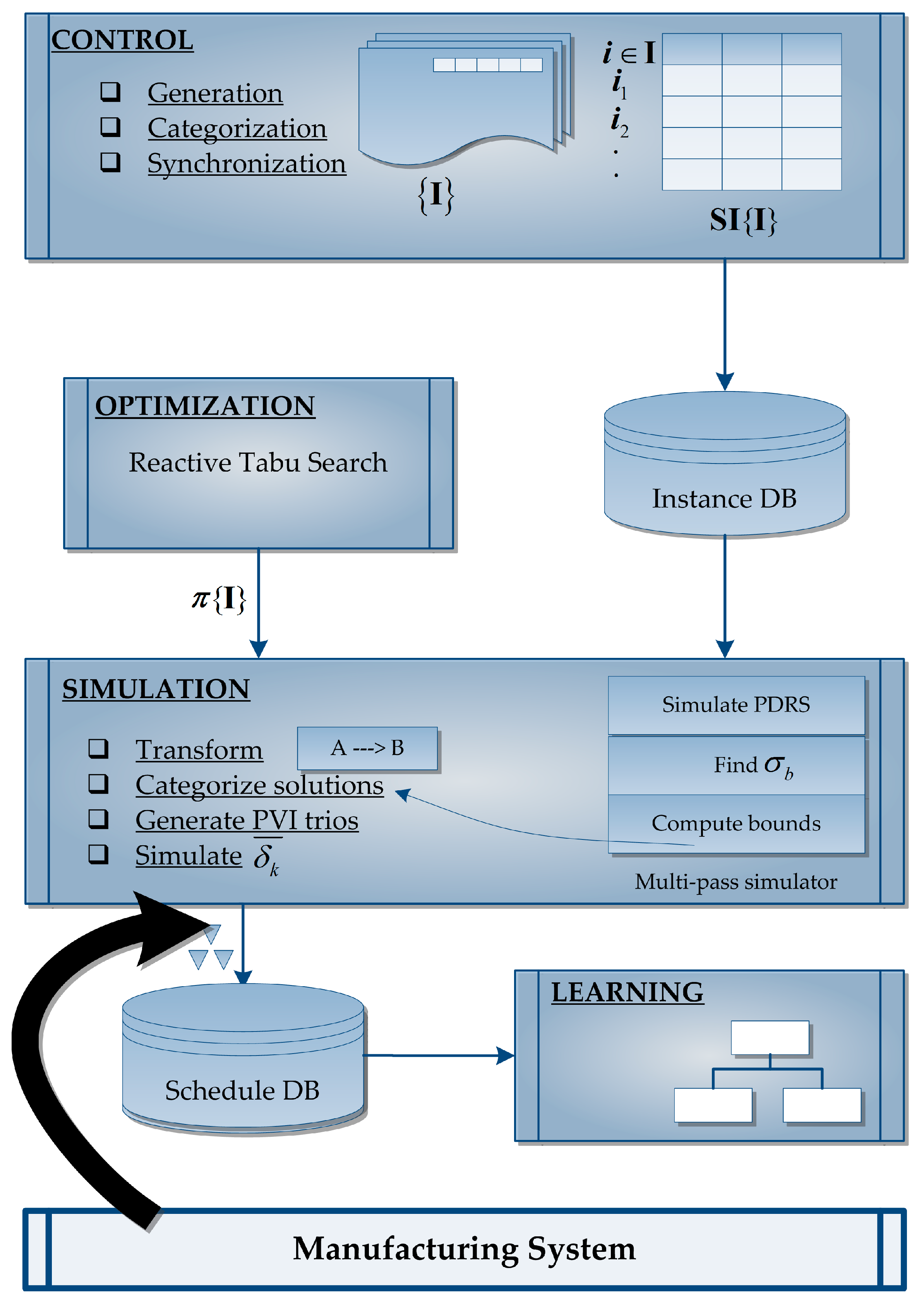

Therefore we couple a dynamic job shop simulation with a. Learning distributed reactive strategies by genetic programming for the general job shop problem. In data mining processes data transformations including data normalisation and feature selection and data mining algorithms greatly influence the predictive accuracy. Earliest due date jobs are performed at each work center according to the order s delivery date.

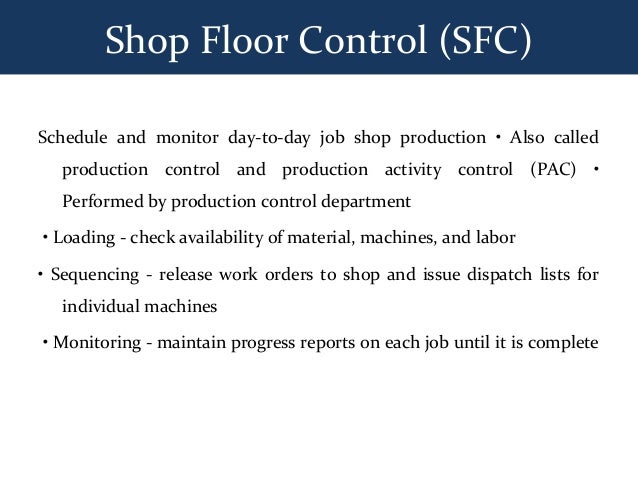

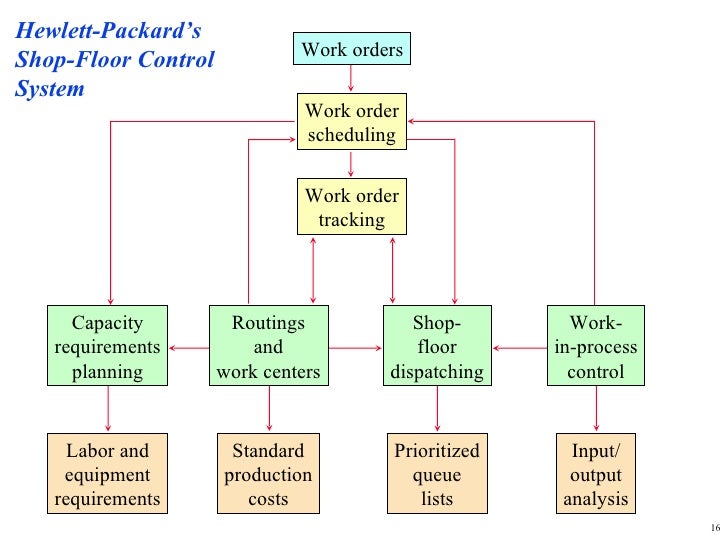

Data mining based dynamic dispatching rule selection mechanism for shop floor control systems using a support vector machine approach. Which of the following dispatching rules ignore due dates. Throughput times are generally high. By controlling the flow of production orders namely timing of arrival and number of units of the job to the shop floor orr improves the system performance.

Be sure the tooling needed is available. Dispatching rules are the most commonly used tools for shop floor control in this industry. For overcoming this drawback order review release orr policy is another shop floor control method used in the present study along with dispatching rule. Work flow through the shop is not constant.

Be sure the material needed is available. First come first served. The purpose of this paper is to develop a data mining based dynamic dispatching rule selection mechanism for a shop floor control system to make real time scheduling decisions. New priority rules can be easily integrated in exist ing software for production control and manufacturing simulations.

A state of the art survey of dispatching rules for manufacturing job shop operations. 2 the classical dispatching rules like first in. Over the years advanced dispatching rules capable of impacting multiple performance measures and utilising both upstream and downstream information in assigning lot priorities have been introduced. International journal of production research.