Do You Glue Engineered Wood Flooring Joints

As an installation method glued down is most suited for either concrete or wood subfloors.

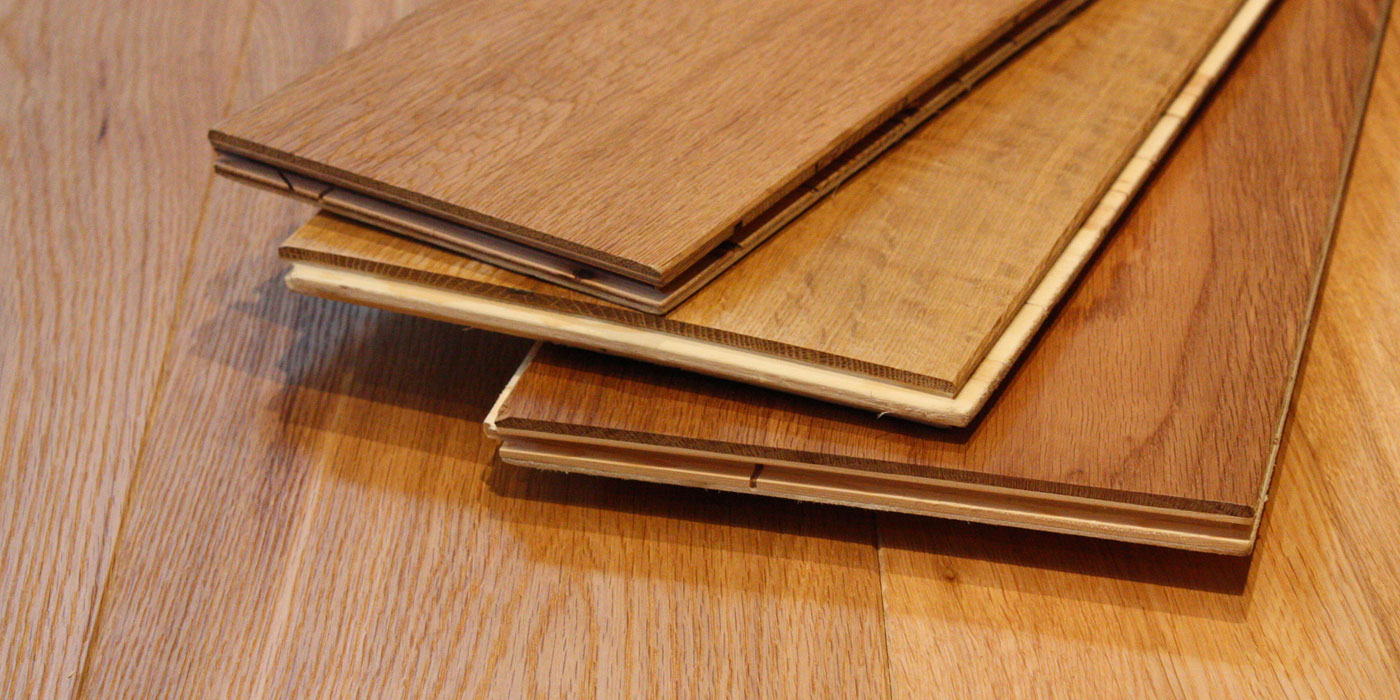

Do you glue engineered wood flooring joints. The bad news is that when you take shortcuts there s plenty that can go wrong. The glue down method of engineered wood flooring installation is typically the most common and creates a highly stable floor. Under normal conditions there is no need to glue the sections. In vinyl click floors end joint peaking can occur which eventually can cause end joints to break.

Very unsightly when this happens. Boards adhere well to the rough surface of the concrete subfloor and therefore lead to less gaps or planks lifting and buckling. As an installation method glue down is particularly suited to either concrete or wood subfloors or any other solid surface where the glue will bond easily. There isn t a wood flooring installer in the business who isn t guilty of taking a shortcut or two on the job site from time to time.

Roofing felt or aqua bar b. If a spill is wiped up immediately unglued pergo suffers no harm. Fortunately most of the problems are easily preventable with a little diligence on the part of the installer. Glued down means using a bonding agent adhesive or glue which is put directly onto the subfloor before laying any of your engineered wood flooring.

Fastening quarter round into the base board and the floating floor another mistake is nailing or gluing the quarter round onto the floating floor. There is no reason to glue down engineered hardwood floor to an underlayment. The good news is that laying wood floors isn t rocket science. The nwfa guidelines state if adhesive is used with nailing follow wood and or adhesive manufacturer s instructions for installing plank flooring.

We recommend waterproof pva glue titebond ii premium wood glue or elmer s probond interior exterior glues are recommended the glue must be applied in a continuous 1 8 3 2 mm bead on the inside top of the groove on both the long and short edges. When working on a clean concrete subfloor the glue down method is often the go to choice. The only thing the glue will do is give you fits and make your install seem tighter. Some manufacturers are recommending glue assisted nailing or use of a moisture retarding paper such as 15 lb.

This is just for initial aesthetics. Within weeks or months the glue will come loose and you will have a floating floor. First check with the manufacturer to see if the glue assist is an acceptable method of installation. Glue down as an installation method for engineered and solid wood floors involves using a bonding agent adhesive or glue that you put directly on to your subfloor before laying your floor.

The glue will never last in a residential setting. In recent years everyone is talking about using adhesive to help with fastening wide plank floors.