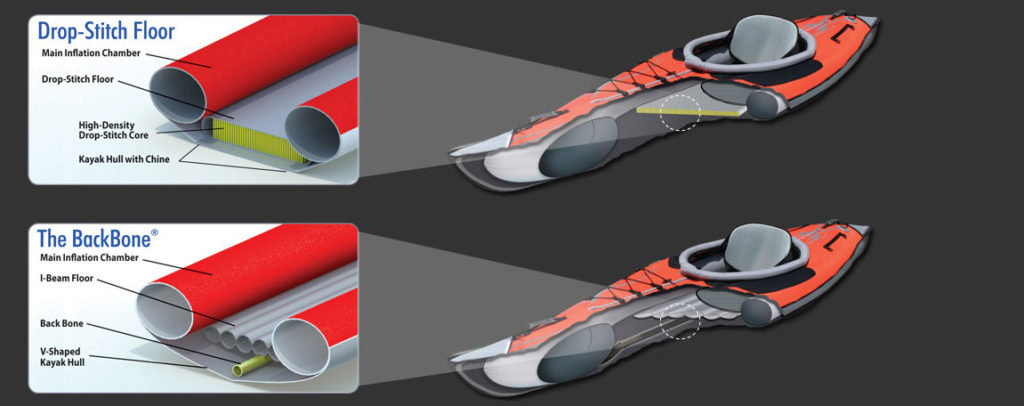

Dropstitch Floor Vs Backbone

You can also see our other articles on the drop stitch floor.

Dropstitch floor vs backbone. When the air pressure goes up and the board wants to go round the stitches hold the flat shape. If you re looking to pack and go drop stitch is the way to go. Drop stitch has become pretty famous lately because of inflatable stand up paddle boards. The seats have built in storage bags.

Click here to view installation video the rigidform drop stitch floor. This video is about the dropstich floor vs the backbone installed on the advancedframs sport. An l beam drop stitch floor and pair of skegs help to improve the boat s handling. There are no limits as to what you can do or have on your deck when you use an aluminum floor.

Either seat can be removed to make room for gear or a four legged passenger. The drop stitch floor rolls up with the boat saving you precious cargo space. There are two seats that are removable with inflatable backrests and seats. When a change is made in the spacing distance between the two pieces of woven fabric it can take over 20 days to remove and replace the required needles.

The boat s spacious sit in cockpit is a sight to behold. This is definitely not ideal for people with limited space capacity. A plastic floorboard will gobble up another 40 x 36 x4 of valuable storage space. Drop stitch is basically a technique of running thousands of stitches from the top to the bottom of the board all at the same fixed length.

Observations on the drop stitch floor versus backbone. These drop stitch sewing machines are marvels of complexity. Aluminum floors are great to have on your inflatable boat a few common examples are leisure boating fishing placing equipment on the deck and having pets on board. You do not want to use the drop stitch floor with the backbone that makes it tippy.

New 7 psi high pressure dropstitch floors from advanced elements.